The electric power which is obtained from the hydraulic energy or energy of water is known as ‘hydroelectric power’. It is the present cheapest mode of power generation when compared to other modes of power generation. The most important part of the hydroelectric power plant is the dam, which acts as the water reservoir.In hydro-electric power plant, potential energy of water is converted into kinetic energy of water which is converted into mechanical energy. This mechanical energy is developed by a turbine which is coupled to an electric generator. Thus electric power is generated by converting hydraulic energy of water into electrical energy.

Hydraulic power plant working

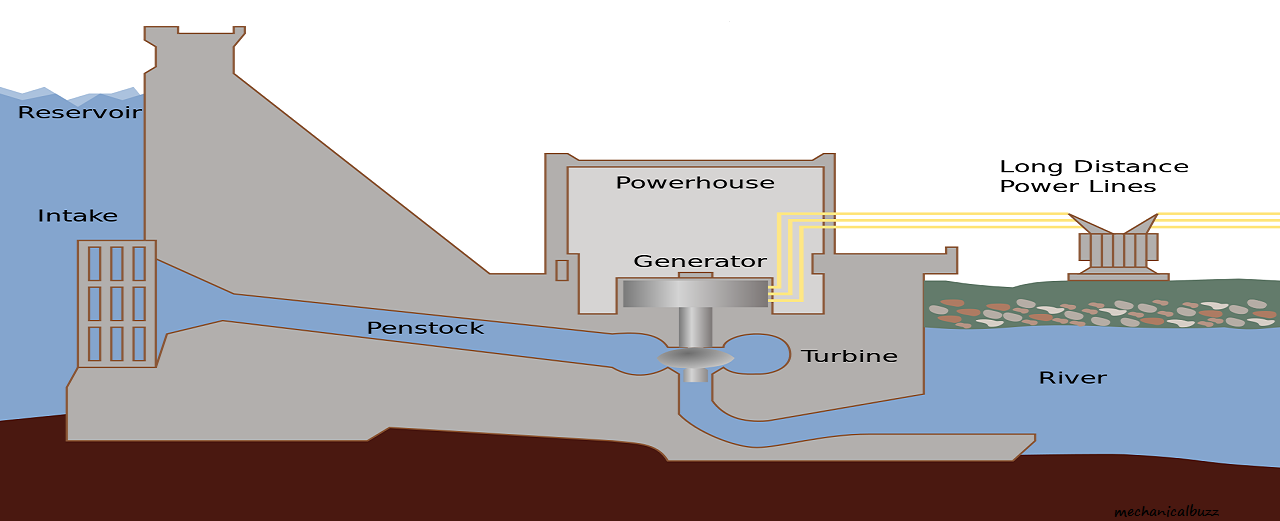

The main requirement for the generation of hydroelectric power is continuous supply of water. For this reason lakes or natural reservoirs at higher elevation are selected and artificial reservoirs formed by constructing dam across a river which helps to store water for continuous supply of water to dam. Selection of lakes or natural reservoirs and constructing dams at high elevation is done to increase the pressure head. Water from the reservoir flows through the penstock which are large diameter pipes made up of steel, wood (in some cases), reinforced concrete. The water is supplied to the turbine with the help of nozzle. High velocity Water strikes the vanes of the turbine, which helps to rotate turbine and produce power. After passing water thorough the turbine it is collected in the tail race. From tail race, the water is supplied to the canals, and the process recycled.

Parts of Hydraulic power plant

1.Dam

2.Water reservoir

3.Intake or control Gates

4.Penstock

5.Surge tank

6.Water turbine

7.Generators

DAM

The dam is the most important component of hydroelectric power plant. A dam is a barrier that holds water, which is primarily used to save and prevent the flow of excess water into a specific region. It should be built at a location where the height of the river is sufficient to get the maximum possible potential energy from water.

Depending on the structure and material used, dams are classified as

1. Timber dams

2. Masonry dams

3. Gravity dams

4. Arc-gravity dams

Water Reservoir

The purpose of water reservoir is to store the water. The water which is stored in the reservoir decides how much amount of potential energy can be generated. The higher the height of the water which increases the pressure head so potential energy also increases, which helps ultimately produce more electricity in the power generation unit.Reservoirs are classified as two types.

Natural reservoir

Artificial reservoir

Intake or control gates

These are the gates which are located inside of the dam. By using these gates the water is released and controlled. These are also called as inlet gates because water enters the power generation unit through these gates. When the control gates are opened the water flows due to gravity through the penstock and towards the turbine. The water flowing through the gates possesses potential as well as kinetic energy.

Penstock

Penstock is a pipe between the surge tank and the prime-mover.And it is the long pipe or the shaft that carries the water flowing from the reservoir towards the power generation unit. The water in the penstock possesses kinetic energy due to its motion and potential energy due to its height. It is of large diameter pipes made up of steel, wood, reinforced concrete. The amount of power generated in the power plant is also depends upon the amount of water flows in the penstock.

Surge tank

The main function of surge tank is to reduce the water hammering effect. When there is a sudden increase of pressure in the penstock which can be due sudden decrease in the load demand on the generator.A surge tank is introduced in the system between dam and the power house nearest.If a pressure drops suddenly, the surge tank fills the fluid from reservoir to the penstock until the pressure becomes constant.

Types of surge tank

1.Simple surge tank

2.Differential surge tank

3.Inclined surge tank

Water Turbine

When water falls on the blades of the turbine the kinetic and potential energy of water is converted into the rotational motion of the blades of the turbine. The rotating blades causes the shaft of the turbine to also rotate. The turbine shaft is enclosed inside the generator. In most hydroelectric power plants there is more than one power generation unit. There are various types of water turbines such as Kaplan turbine, Francis turbine, Pelton wheels etc. The type of turbine used in the hydroelectric power plant depends on the height of the reservoir, quantity of water and the total power generation capacity.

Generators

It is in the important part where the electricity is produced.An electric generator is a device that converts mechanical energy obtained from an external source into electrical energy as the output. The shaft of the water turbine rotates in the generator, which produces alternating current in the coils of the generator. It is the rotation of the shaft inside the generator that produces magnetic field which is converted into electricity by electromagnetic field induction. Hence the rotation of the shaft of the turbine is crucial for the production of electricity and this is achieved by the kinetic and potential energy of water. Thus in hydroelectricity power plants, potential energy of water is converted into electricity.